How about galium nitride fets- like these https://www.mouser.com/ProductDetail/GaN-Systems/GS61008T-MR?qs=sGAEpiMZZMshyDBzk1%2FWi0w8OutPcgKpurytXVZkEsLxs%2FmiPHaVVw%3D%3D

How about galium nitride fets- like these https://www.mouser.com/ProductDetail/GaN-Systems/GS61008T-MR?qs=sGAEpiMZZMshyDBzk1%2FWi0w8OutPcgKpurytXVZkEsLxs%2FmiPHaVVw%3D%3D

Hi ,

supporter for the feature request .

.

GaN FETs will be a great feature addition, i think the limitation comes with the continuous current capacity (not sure but is my analysis).

There is an other company (EPC) as well and this video is their showcase of motor drivers for robots and ebikes

https://www.youtube.com/watch?v=HfPwZW8BqDw

There are few GaN FETs with integrated gatedrives - https://epc-co.com/epc/Products/eGaNFETsandICs/EPC2152.aspx

The GaN FETs are better interms of thermal properties as well

These are just switches, they are already supported by the firmware, but... Low current limits, high RDSon, expensive. What's the point?

NextGen FOC High voltage 144v/34s, 30kw (https://vesc-project.com/node/1477)

I think the point is super high speed switch frequency for a more quiet operation.

https://epc-co.com/epc/GaNTalk/Post/20067/Reduce-Audible-Noise-in-Motor-...

Probably not a need for e skate but some robotics (and other) projects could benefit.

I'm making new hardware for VESC using GAN FET. At the first stage I try EPC9146 and STM32F405.

Problem. Resistance and inductance are not measured. Tell me which files to look in first.

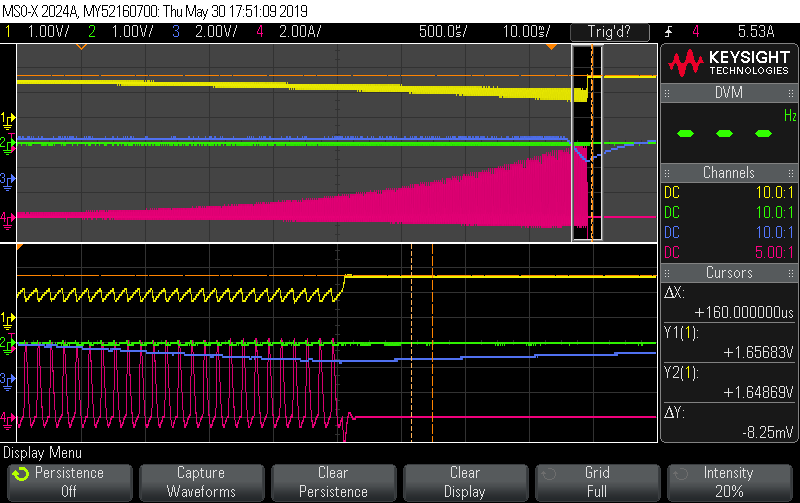

ch1 - PH1 I

ch2 - PH1 V

ch3 - Fault

ch4 - I

https://github.com/karu2003/bldc/tree/EPC9146

Where can i change the frequency of the PWM to measure resistance and inductance. It seems that the measurement frequency does not depend on the user PWM.

And the MCU is not crashing at 100kHz? I haven't seen it being stable anywhere above 45kHz.

NextGen FOC High voltage 144v/34s, 30kw (https://vesc-project.com/node/1477)

For this design you have the same code. It doesn't work for me.

When measuring resistance, i get Fault. This - a small PWM frequency for Ramp UP or a large ramp. Maybe. I am applying your recommendations. When I increased the PWM to 100kHz, I set FOC_CONTROL_LOOP_FREQ_DIVIDER 3. I haven't reached the point MCU crashing. :) Doesn't work for me even at 45kHz.

I think there are two separate issues here. First, the STM32F405 MCU is not fast enough to run at 100kHz PWM. Most VESC implementations settle to run at 30khz. I like to run it at lower, 20kHz, for example, to further reduce switching losses. 20-30kHz is enough in most situations where mosfets are used. Of course, to take advantage of GANs, you need to be running at least 100kHz or more. This is not to say you can't be running GaNs at 40kHz or so but that defeats the purpose. The second issue is that you probably need to drop the frequency when detecting to get consistent results at different voltages/states of charge. I get most consisten results at around 3kHz. Inductance measurements will vary a lot with the frequency.

NextGen FOC High voltage 144v/34s, 30kw (https://vesc-project.com/node/1477)

I started with KIT. the motor is spinning. :) resistance and inductance are measured. learned to raise the measurement frequency to 80 kHz.

I plan to check other kits from EPC. Would you like to add them as boards?

Making a board with GaN mosfets wouldn't be hard but I am struggling to justify the effort. 3x higher cost with 1/2 current handling capability of a silicon mosfet. The only benefit I am seeing is smaller DC link requirement and a few % of efficiency gain. Wouldn't SiC make more sense?

NextGen FOC High voltage 144v/34s, 30kw (https://vesc-project.com/node/1477)

I need to go to high PWM. the higher the better. I need to give from electrolytic capacitors. Pressure and depth are not friends for ELCO. acoustic communication operates below 100 kHz.

There needs to be a PWM/control loop ratio option to make use of GaN fets. I asked someone a long time ago and they said they had made a custom build that did it with only a few lines of code changed but it was many firmware versions ago so it may not be as simple anymore. TI Instaspin has a similar solution on their dev boards, you just sent a divider between PWM and control loop, for example at 100khz you could run a 4x divider and the control loop runs every 4th PWM cycle giving a 25khz control loop.

I'm not sure if you can possibly squeeze more performance out of the motor controller leveraging GaN, you can run much shorter dead times and there's no reverse recovery. I'm not sure if the higher switching speeds combined with lower dead times can potentially be advantageous for sensorless motorcontrol, someone with better understanding of the algos and software would have to answer that.

The latest EPC GaNfets do look nice they're close to silicon ones in price, if you can run them at 100khz it's feasible to use only ceramic caps.