Dear Forum,

I've build a 3D printed Axial Flux Motor (okay the rotor is already made out of aluminum). The Motor has 24 stator coils (3x8) and 32 poles. (since the arrangement is a little different to radial flux it is really 32 poles (vs 16 pole paires). One stator drives two rotors (each has 32 poles). The diameter is about 160 mm. The windings are 3x0.8mm copper with 9 windings per coil.

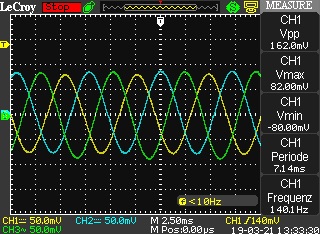

I powered it first with a regular hobby king ESC (3S; 30A) pretty much without problem; it just needs a firm manual input to speed up initally. Roughly it draws 4.5A with a 3S LiPo, no load (the bearing are quite big due to the hollow shaft and cause a lot of initial friction). I checked the phases with an oscilloscope and all three are there (120° apart).

Recently (yesterday) I received a VESC6plus. I updated the firmware and performed the motor detection. As expected, L is very low with 4mH. During calibration, the VESC accelerates the motor first slowly, than it seems like that the electric field rushes away and the motor stops. In the next step, where the motor is only turned very slow left/right it follows the the field again.

However, when I want to control it with the VESC Tool, the motor is either "very bumpy" (independent of the settings, no reaction when ERPM is <1000rpm or when the duty cycle is very little), and it only "jumps" from one position to the next one (the direction is correct) without that you really can call it "spinning". If the ERPM is set too high (>5000rpm) or the duty cylce is set high (0.5 and up), it appears again that the electric field rushes away.

I assume that the mass (+friction) is too high to follow the field when the acceleration is too high, or the inductivity is too low? But then (second case) it would never turn, but it does at the very beginning at the test and when the slow position turn commands are given during calibration. Is there a possibility to slow ramp up to a speed? Would a position sensor help? Or do you see any other reason? (I assume that all three phases of the windings are correct out of the oscilloscope measurements)

Kind regards,

Tobias

Ironless 3D printed axialflux Motor with VESC6+

Hey all,

Hmmmm....I would really like to know the settings of the detection process when the motor slowly turns a little bit left/right...the motor drives at this point nicely, but besides this, it looks either like freaking "cogging" (but it's an ironless motor) or, it just gives a high pitch noise. I tried to play around with all the settings but neither with luck, nor with "knowledge" archived much (except that the motor jumps happy around each time it makes this tiny movement). Can anyone give me a hint what and where I should start my changes?

I tested the VESC with a small outrunner, that works (low speed is bumpy as well, but at least it turns at high speed).

Kind regards,

Tobias

P.S: Maybe this topic fits better in "Third-Party HW". My fault, sorry.

So I got it to run, a little crumpy at the beginning, but then turning very slowly (about (2rev/sec). Not sure what settings I used exactly because I changed something and suddenly it worked. Most likely it was set to BLDC instead of FOC. And ERPM max was most likely low (because the 2rev/sec was also the max speed). Slightly increased the start current push value.

Besides this, the current draw was very high (up to 15-20A at 13V). When I used the Hobby King ESC it was at high speed (700-1000rpm) about 4A.

I guess I need more time to figure out all parameters...........

Are you sure the inductance is 4mH? It would be more like 4uH... And at 4uH, V=L di/DT, with 12.6v that's 3.15A/microsecond current ramp rate, pretty darn quick! Increase your PWM frequency as high as you can and see if that helps (it should).

Hi guys,

I have quite the same problem. Iron-less axial flux, 110mm diameter, 24 poles, 6S, 4A current draw at idle run. VESC tool might not auto-detect the parameters because we have no salience. ESCs usually use salience/reluctance difference when controlling the motor. This is also probably the cause of high current consumption at idle run.

I would appreciate if you can share your latest achievements/parameters whether you managed to set the ESC properly.

@bgdwiepp, it's a good idea. I will give it a try.

Hi guys,

I've been trying to run my ironless axial flux BLDC with VESC 4.11 since few weeks now. The motor gets to turn but the result is not quite as expected. Here are the symptoms I'm experiencing:

Do you have any suggestions? Is there a way to simulate the Auto Detection algorithm manually?

Hello, VESC & Ironless Axial Flux Nerds!

After a few years pause, I started again, with a new motor. It's again a axial flux, but this time a Double Disc Rotor, Double Stator design (=2x3phases). The magnets are arranged in a Halbach array. 18slots/20poles. It's an outrunner.

Last weekend I had the chance to run it up with a VESC 6 I have (tested each stator separately).

So, weird thing. When doing the FOC wizard, it runs up very smoothly. No problem at all.

But any attempt to control it via the manual controls fails, independent from Current, Duty or RPM control.

Can anyone highlight me the diffference - or what is the FOC detection doing differently?

Thanks!

Tobias

Hmmm....slow reply here....even though you have to pay $$ to participate here.

I've today tried all different settings, but non of them really worked (also increased the switching frequency to

It is still strange....FOC detection runs perfect:

But whatever I try in the experimental tab (Duty, Current, RPM) fails big time....sometimes it slowly "turns" in Duty cycle.

Has anyone a hint? (Maybe one of the team member to whom the payment for the VESC tool goes and who earn money with selling original VESC hardware?)

Kind regards,

Tobias