I recently had a VESC 60HD-T failure that I'm a bit perplexed over. I had run the automatic setup wizards is VESC Tool and for the most part seemed like no-load operation was working very smoothly. The only issue I had was that measured battery current (via current probe) was quite a bit higher than what the SW was reading -- I'm mentioning that here as I will go into further current-based issues later so there may be a link.

I was running in FOC sensorless mode, which I determined through comparison to give better results than with an encoder (I've also got an ABI encoder mounted on the motor). However I only was comparing at lower ERPMs since it was my understanding that the encoder could help at slower speeds, and although I did see that it was a little better at very slow speeds, I was having issues around the crossover point when running in hybrid mode, so I decided to just go full sensorless since my application wouldn't require such slow speeds anyway.

Anyway, the real issues started cropping up when I started to apply load torque. I've got a test set-up with a brake that allows me to apply variable torque on the motor. I started by spinning the motor at max speed (I'm using the 'D' control at the bottom of the VESC Tool) - at the max of D 0.95, I hit around 95000ERPM. Then I start applying load torque. I ran into two issues: first of all, the motor current (both as measured in software and as measured with current probes) was generally higher than expected given the Kt of the motor. The measured current was somewhere between 1.5x - 2x what I would expect for a given load torque.

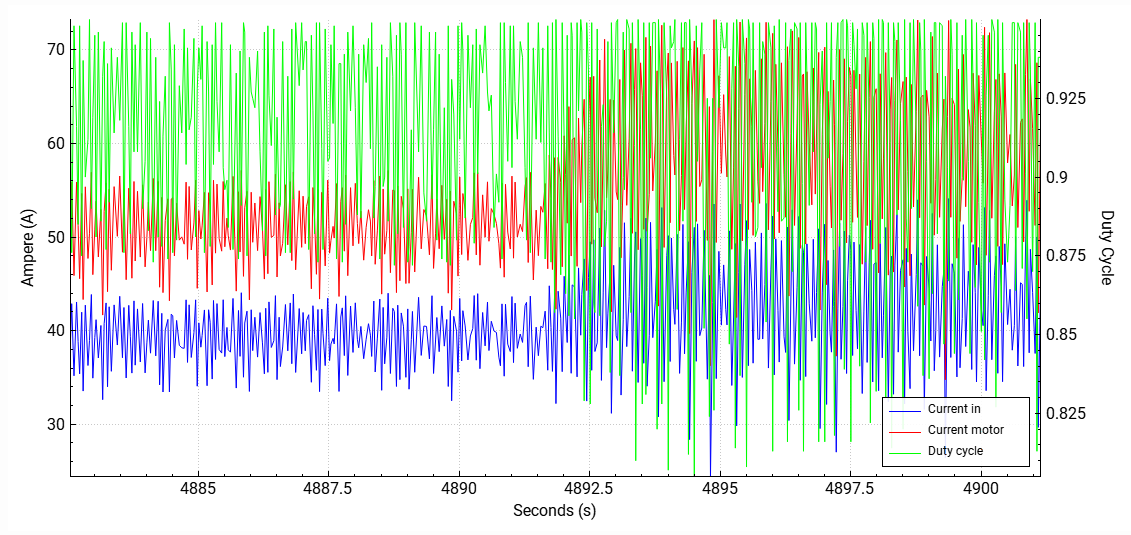

Max continuous current for the VESC 60HD-T is 75A, so I had a motor current limit setting of 70A. Starting at around 50A motor current, I start to see some big oscillations of the current, increasing as the current goes higher:

You can see around 4892.5 seconds when I increased the torque further to an average current of about 60A, the oscillations look to be about 30Apk-pk.

I ran some testing like this, but then on the second or third attempt is when the controller failed with a pop and puff of smoke.

I guess I have three main questions here:

1) why did the controller fail when it looks like the current was staying under the 75A limit of the controller (or at least was under it most of the time, and the 75A rating is continuous).

2) what can I try to eliminate these current oscillations? Would this be a question of PID tuning?

3) why is my current higher than expected in general?

Any help would be much appreciated!