Hi,

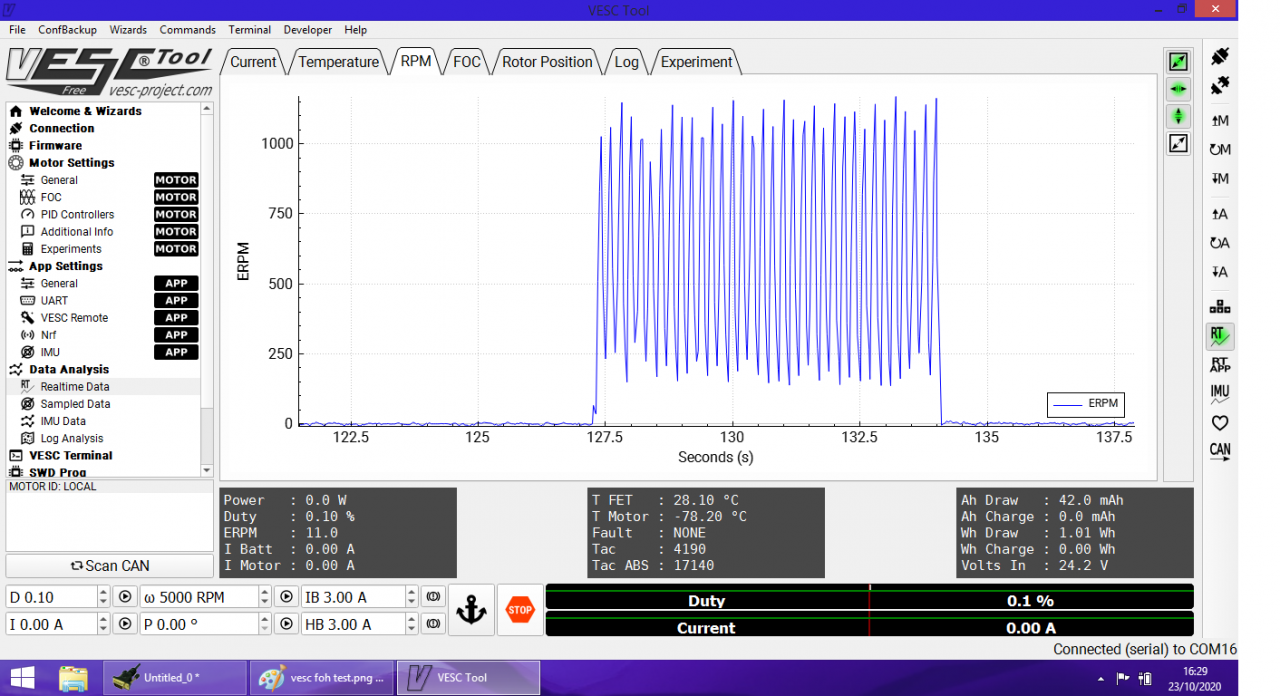

I am trying to get my brushless DC motor running smoothly in FOC mode. The motor parameter detection runs swimmingly, with the resistance detected and the spindle spinning up smoothly during the flux linkage detection. However after applying these motor settings, when setting the device to run at any speed, the spindle spins erratically in both directions not even making a full revolution. I've got a video below showing what's happening:

It's being powered off a 15A 24V PSU, and I'm not getting any power warnings or faults. The motor is a KaVo 4010. In BLDC modes the motor seems to run okay, though struggles to keep a consistent speed below 10k rpm varying it's speed by about 500rpm

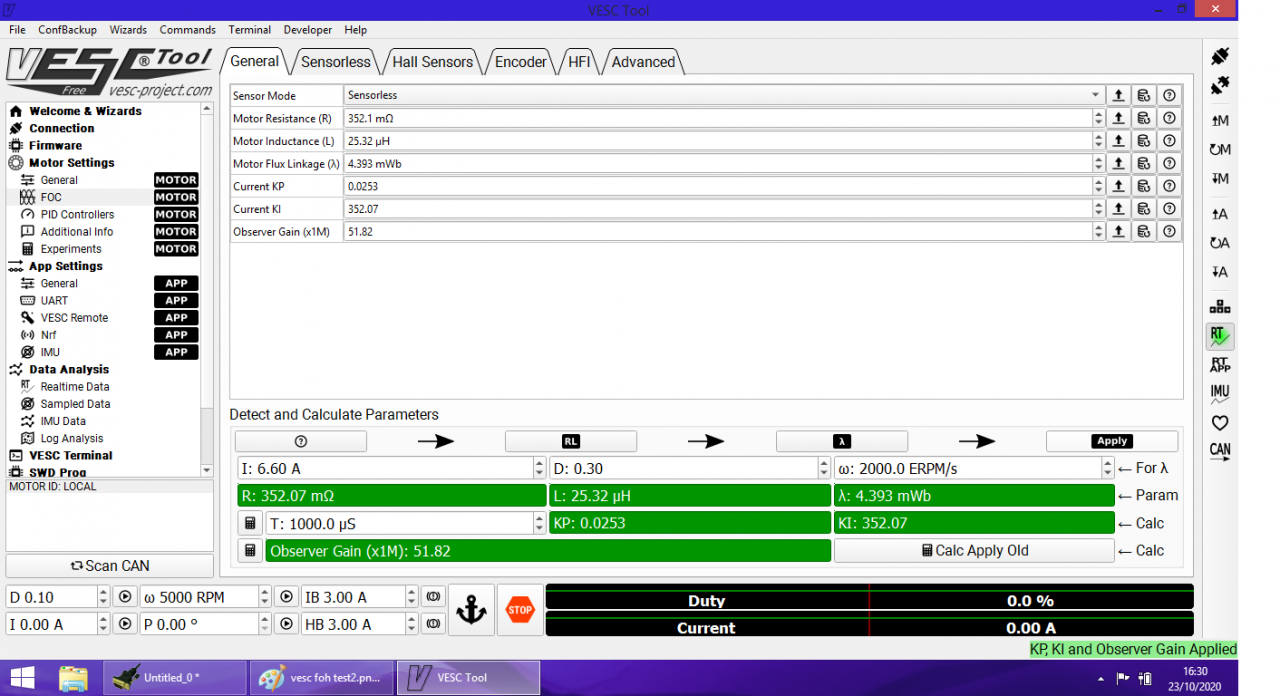

Here are my motor settings and some graphs:

That resistance value is CRAZY high, are you sure that is right? What motor does the spindle use?

Yeah, I believe it may be. There is about 1.5m cable between the bldc and the controller. It is worth mentioning this motor used to be connected to another properitety controller that ran it fine. The thing I find really strange is that the detection routine can spin the controller absolutely fine, maybe it isn't using FOC mode to spin the motor?

If bldc mode is spinning better it might be simpler just to tune the speed PID loop to get it to hold speed a bit better. Foc and bldc use different values for the PI speed loop. For a spindle motor always running at high speed and low load the advantage from foc is probably not that large compared to on an electric vehicle

I confess I haven't looked at the PID values too much, either in FOC or BLDC mode. Would invalid PID values be causing the problems I'm seeing in FOC mode?

In terms of the BLDC mode, I hear quite a lot of sputtering at low speeds and the duty cycle is pretty erratic, I assume that would be helped by the PID values. Is there any nice information about tuning PID systems? I'll have a look for some more details on it.

For reference it's a KaVo 4010 motor. Details can be found on page 16 of this brochure: https://principle-eng.co.uk/wp-content/uploads/2018/10/180908_Sycotec_Sp... though there doesn't seem to be a proper datasheet out there. I have just realised it's a 3 phase asynchronous motor instead of a BLDC motor. That would probably explain a lot of the issues I've been having, though people say FOC mode should work better for this type of drive.

I'm encountering the same issue. FOC calibration spins the motor smoothly, but any duty cycle setpoint (0.2 etc.) causes the motor to bounce around and draws much more current (~4x). Here's a video showing the difference:

My control requirements are pretty lax (similar to the spindle use case) and there's just a simple inertial load.

I was previously using a simonK ESC, but that was pretty noisy and burned out motors when attempting to start with a higher inertial load.

Thought I'd give sensorless FOC with VESC a shot, which seems more promising.

Using an A2212 1000KV motor.