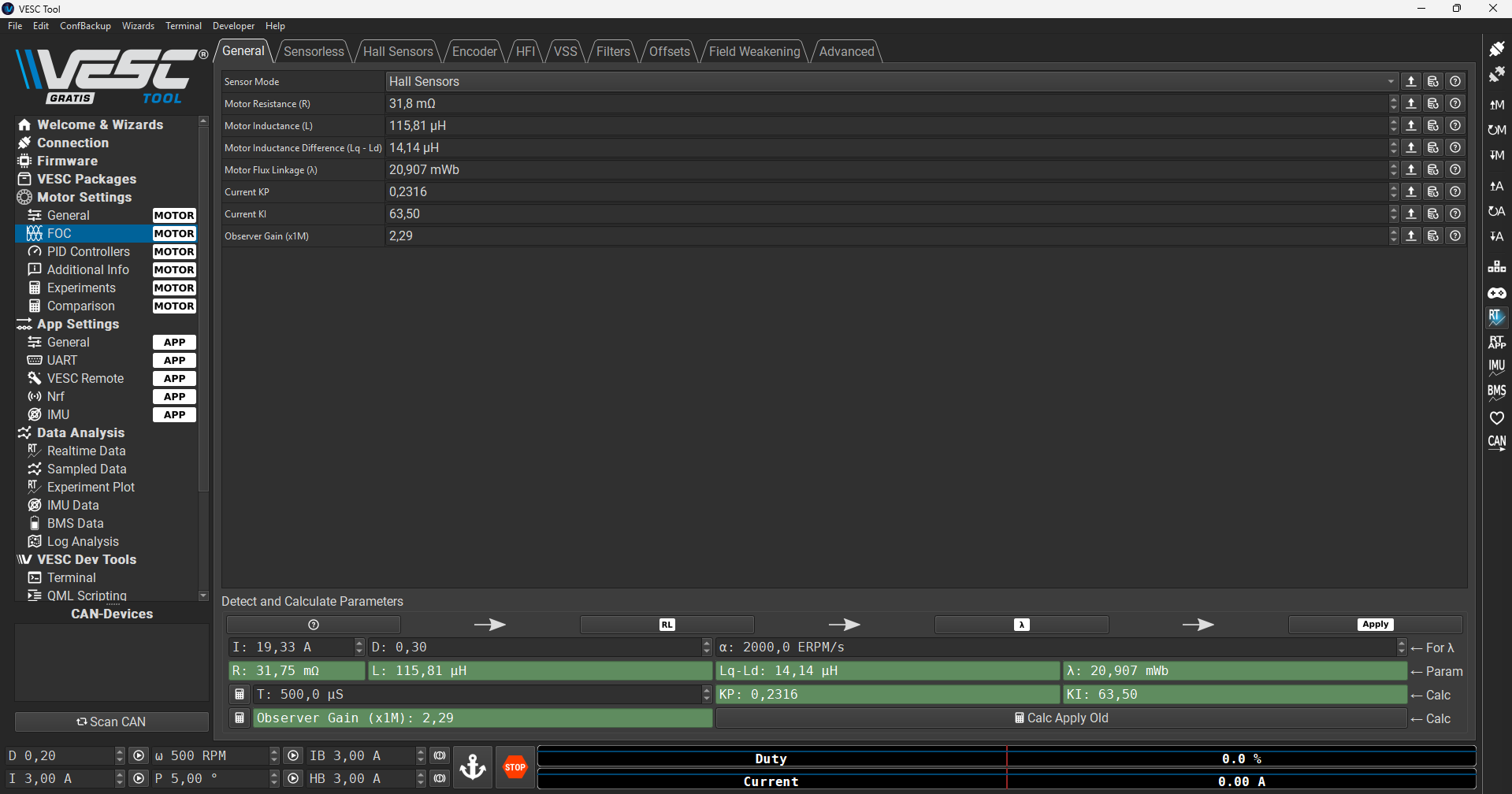

For a powerful robotic arm project, I am using a MY1020 3kW motor with 6 poles and a Hall effect sensor, along with a 100:1 harmonic reduction and a Flipsky75100 configured in FOC. The entire setup is powered by a 72V, 40A power supply. Everything works fairly well except at low speeds. Below 500 ERPM, the motor has no torque and makes clicking and whistling noises, as if the rotor is not "catching" the rotating field.

I have performed automatic FOC parameter detection and tried changing various parameters, but nothing seems to work.

Do you have any tips? Am I missing something, or am I simply asking too much of a motor that may not be designed for this level of precision?

Thanks !

The only tip I know would be to go to FOC - Sensorless and set Openloop to 0 ERPM, so you "force" it to use the Hall Sensors.

Id try going to foc-sensors-sensorless erpm and raise it to 5-6k erpm. Ive had much better luck that route vs 0 openloop.

If those both dont help, just fit an encoder on the motor.